Blog

TOSHIBA Chiller – Universal Smart X EDGE solution

A chiller is a cooling device that can produce cold and transfer it to the water circuit. The chiller is composed of two circuits, in the primary circuit the compressor cools the refrigerant and the secondary circuit cools the water circuit with water.

Eight intelligent functions

At first glance, the new TOSHIBA heat pumps make a competent impression. USX Chiller devices are delivered to the installation site in a compact modular form with a distinctive X-shaped design. The space-saving combination of up to 128 modules side by side can achieve a total output of up to 25,600 kW. This enormous capacity can be realised in a theoretically unlimited number of gradations, from 5% in the case of the Single unit up to maximum capacity, thanks to the modularity of the system and the perfect part-load performance. Our features illustrate how this intelligent system design achieves significant savings in both area and energy resources, as well as perfect fail-safes.

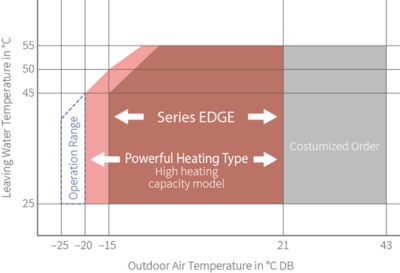

1. USX EDGE RELIABLY PROVIDES HEAT AND COOLNESS ALL YEAR ROUND

USX Edge equipment specialized for year-round heating operation is called POWERFUL HEATING TYPE (pHt). They reliably produce pumped hot water, e.g. for production processes or for heating buildings, up to outdoor temperatures as cold as -25 °C or as tropical as +43 °C.

Irrespective of whether the cold water production is used for any of the above purposes:

– comfortable air conditioning of a large building,

– Processes,

– computing centres,

– food technology,

– cooling rooms,

– medical technology,

– artificial ice rinks,

– inlet temperatures from -15 to +30 °C cover every requirement. Operation at outdoor temperatures from -20 to +46 °C is guaranteed.

2. DISTINCTIVE DESIGN X OPTIMIZES AIRFLOW AND NEEDS LESS INSTALLATION AREA THAN CONVENTIONAL SYSTEMS

Space saving = cost reduction

The patented X design covers several components with its development: it allows for a smooth installation of the individual devices as well as highly efficient air routing between them.

The distance from walls and other objects can therefore be kept as low as possible.

Seamless access to maintenance-relevant components such as the compression unit is also guaranteed thanks to the intelligent design.

The hydraulic system with inverter pump is ready for immediate connection and is space-saving integrated in the compressor section.

The water connections, which are retracted thanks to the distinctive Edge design, also contribute to the efficient management of the area. The 300 mm recessing of the compressor section compared to the heat exchanger section brings spatial advantages when the modules are installed in parallel.

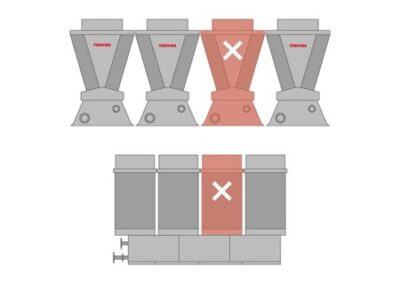

3. MAXIMUM FAILSAFE AND REDUNDANCY THANKS TO 4-IN-1 MODULE CONCEPT

The 4-in-1 module concept ensures maximum operational safety and risk management thanks to four separate cooling circuits. Each circuit has a TOSHIBA inverter-controlled double piston rotary compressor and two refrigerant/air heat exchangers – the two circuits share one refrigerant/water heat exchanger.

However, it doesn’t always have to be a dramatic circuit failure – on a typical working day of a heat pump, resp. Finally, defrosting during heating operation or periodic maintenance of the equipment are also part of the refrigeration system.

Even in these standard situations, the USX system reacts sovereignly: the defrost operation is alternated – only the circuit that is currently defrosting stands still, the other three circuits of the module continue to produce pumped hot water (Continuous Heating). This can eliminate the need for an additional buffer tank.

Only a small part of the entire system is temporarily out of service during the maintenance work. This is a unique solution from TOSHIBA.

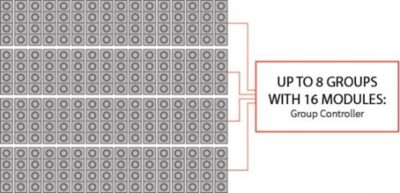

4. SYSTEM CAPACITY FOR HEATING AND COOLING UP TO 25 600 KW WITH MODULAR COMBINABILITY

The possibility of modular combinations allows maximum flexibility in planning, operation and, if necessary, the use of the system. Expansion.

Thanks to highly efficient inverter technology, small part-load outputs as well as large outputs in the megawatt range can be achieved under extreme conditions.

It doesn’t matter whether you use a single module with a rated output of 150 kW or a combination of modules with several megawatts – the intelligent control unit system can handle any combination. And you’re managing costs with only three control devices:

Unit-Controller (UC):

It is included as standard in every single module and optimises the four refrigeration circuits by controlling the inverter compressor. It also ensures that the outlet water temperature reaches the preset temperature and controls the integrated inverter water pump.

Module-Controller (MC):

It is an optional control unit and can control a Unit-Controller of one group of up to 16 modules.

Group-Controller (GC):

It is also an optional control unit and can control up to 8 groups with the corresponding module control units.

5. ENERGY-EFFICIENT PART-LOAD CONTROL UP TO 5% VIA THE PROVEN TOSHIBA DOUBLE ROTARY PISTON COMPRESSOR

The double rotary piston compressor with inverter control from TOSHIBA’s own development and production forms a strong link in the system. This team demonstrates its longevity, efficiency and performance every day in literally millions of residential and commercial air conditioning systems around the world.

As one of the 4 elements in each USX module, the compressor creates the prerequisites for significant system benefits: part-load operation of the module up to 5% of the rated output, an outdoor temperature range from -25 °C to +46 °C – therefore supply temperatures from -15 °C to +55 °C can be realised.

The choice of refrigerant at TOSHIBA is also clear. The most modern, economical and environmentally friendly refrigerant currently in use here is R32.

6. LOW INVESTMENT AND OPERATING COSTS DUE TO THE SERIES REDUCTION OF THE ELECTRICAL INSTALLATION POWER

The USX Edge benefits from the suppression of higher harmonic waves thanks to the PWM converter: the TOSHIBA system is thus able to operate extremely efficiently with a performance index of 99% thanks to the reduced operating current.

From this relatively complex fact, three specific advantages emerge:

1. Installation cost savings

Electrical equipment for power supply (cable cross-section and safety devices) can be dimensioned in smaller dimensions

2. Configuration cost savings (No additional costs are incurred when using active higher harmonic wave filters)

3. Cost saving in the enterprise (due to the high active power factor cos φ, the electricity consumption in the enterprise is reduced)

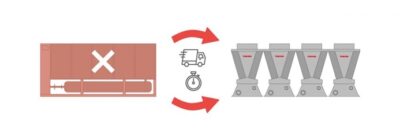

7. STANDARDIZED EQUIPMENT CONFIGURATION ENSURES YEAR-ROUND AVAILABILITY

Conventional Heatpump Chiller installations often suffer from an over-supply of configuration options.

In practice, this leads to complex and lengthy configuration and delivery procedures.

The TOSHIBA USX EDGE Heatpump Chiller introduces a completely new concept to the market for the first time:

Selected, standardized pre-configurations that meet customer needs, allow for permanent stocking as well as the fastest dispatch. Even for spare parts!

All this from a warehouse in Vienna – without restrictions such as. company-wide holidays during the full season.

Of course, special designs with optional options and extensive accessories are also possible.

TOSHIBA also operates this classic built-to-order concept with short delivery times.

The unique product concept allows the replacement of an existing Heatpump Chiller system – e.g. in the event of a total failure – within a few working days – without expensive rental refrigeration equipment.

8. MOBILE MONITORING OF DEVICES AND CONSUMPTION VIA A SIMPLE APP

The Flash Monitor System from USX Edge works with a WLAN SD-Card in the Chiller module, which communicates with the corresponding application on the Android tablet.

This tool serves everything from the simplest commissioning and transparent data management.

For example:

– displaying the operating time for all components,

– calculation of the amount of water required,

– display and history of error codes,

– definition of maintenance cycles for compressors, fans and pumps,

– display with real-time data for all operating pressures and temperatures,

– comparison of real data and stored data,

– clear trend graphs of all operational values,

– display of pressures and temperatures in the animated cooling circuit,

– system reports with export function,

– many other features…